-

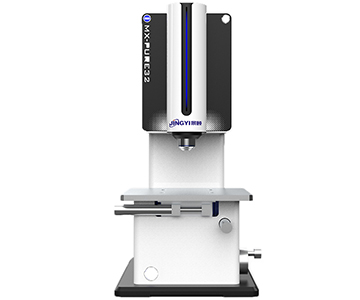

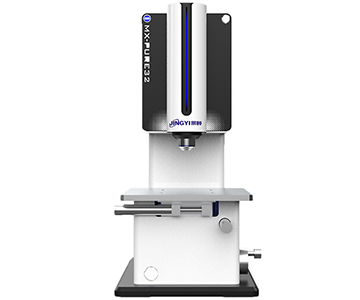

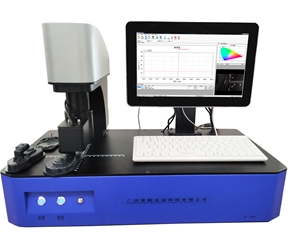

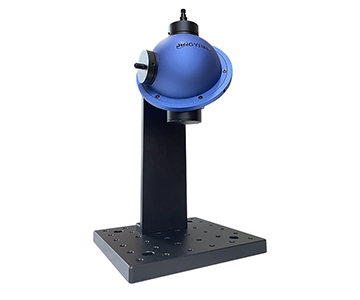

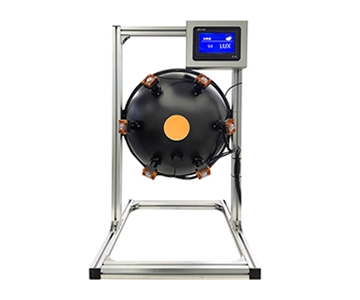

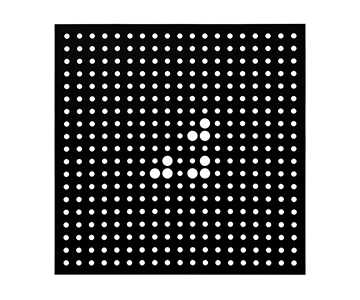

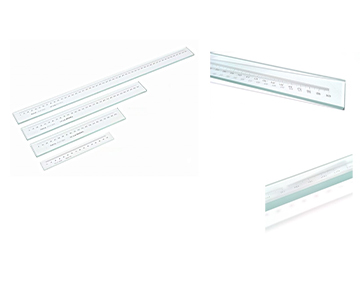

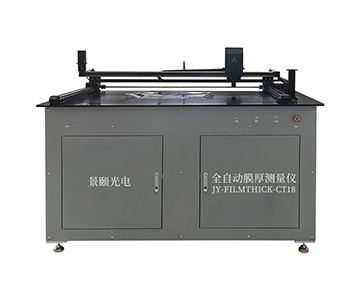

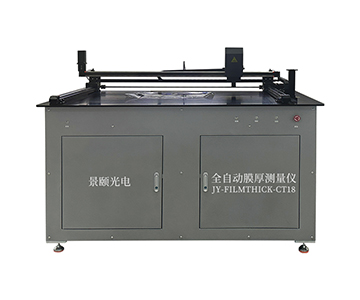

Film thickness measuring instrumentBenefiting from the strong demand in automotive electronics, industrial electronics, Internet of Things and other application fields, the corresponding demand for chips and sensors is strong, which increases the demand for semiconductor silicon wafers. Coating is one of the important steps to prepare efficient crystalline silicon. In order to test the quality of silicon wafer coating, Jingyi Optoelectronics has developed film thickness measuring instruments, semi-automatic film thickness measuring instruments, online film thickness measuring instruments and other products to improve the production efficiency and product quality of the factory and jointly promote the localization of semiconductor silicon wafers

-

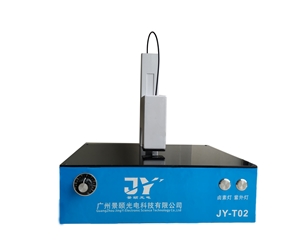

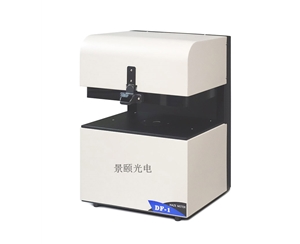

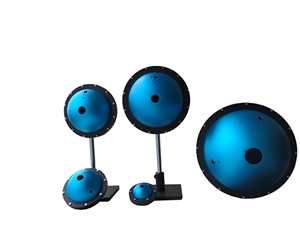

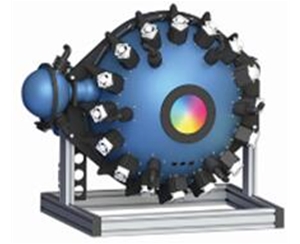

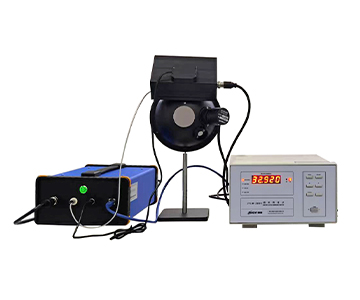

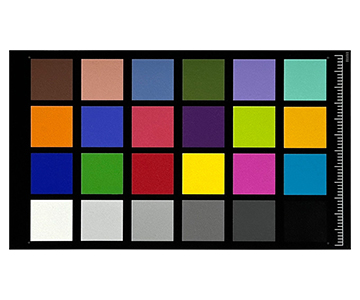

D8 reflectivity meterIn the field of solar cell manufacturing, it is of great significance to obtain the reflectivity of solar silicon for production control and research. Jingyi Optoelectronics has developed a D8 reflectivity meter based on the characteristics of solar cells. The product is used in the monitoring link of the cell flanneling process, providing customers with an effective detection scheme to control the quality of the cell and reduce the loss

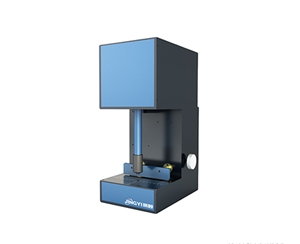

-

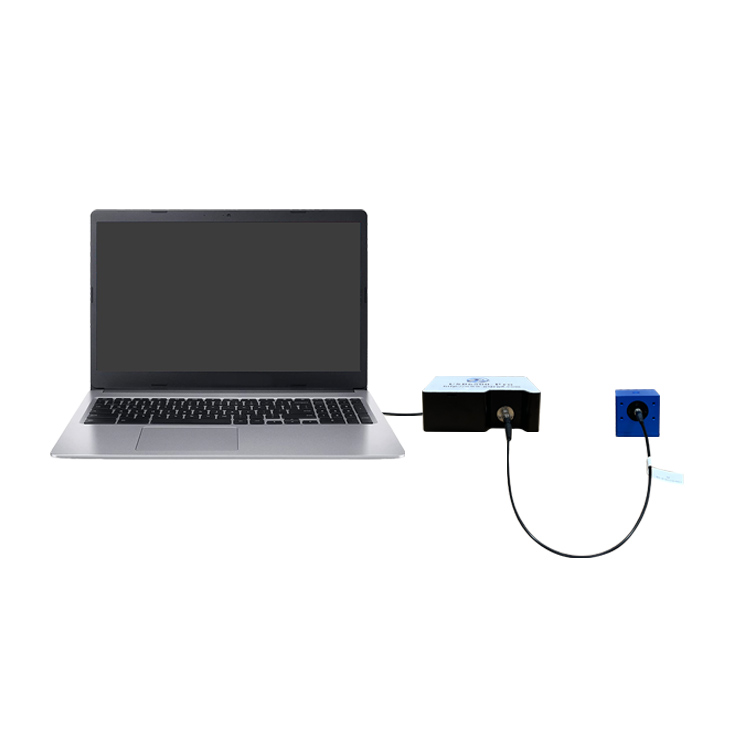

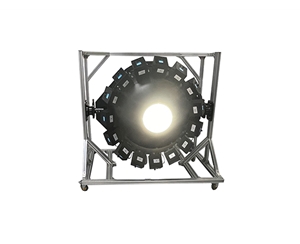

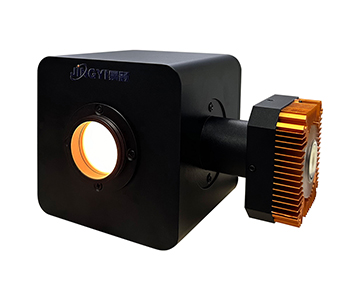

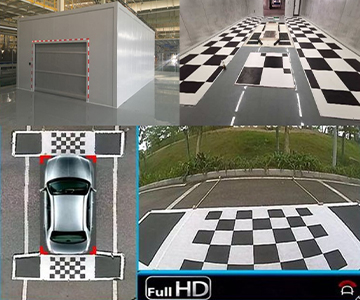

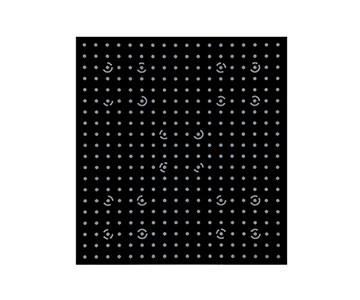

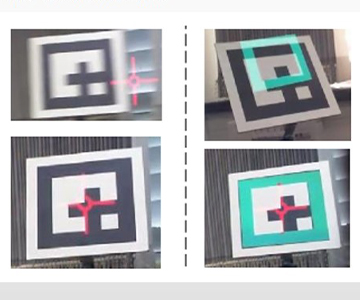

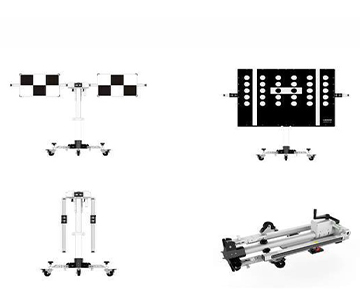

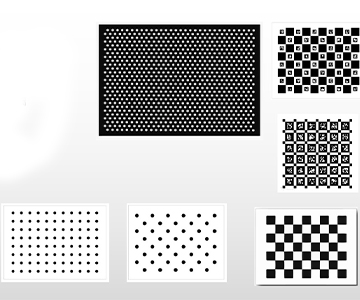

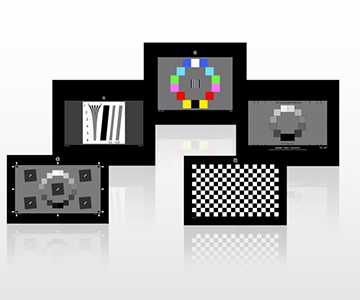

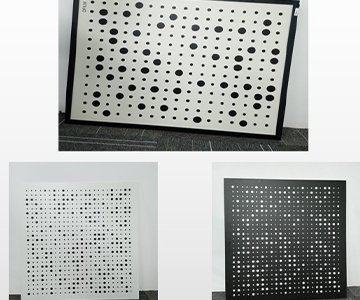

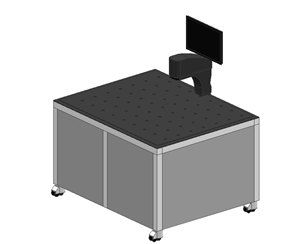

Laser spot quality inspection scheme for semiconductor lasersWith the development of lasers in medical, industrial production, laser printing, laser welding, laser communication and other application fields, the requirements for the quality of spot imaging size, shape, energy distribution and so on are getting higher and higher. Therefore, the analysis and measurement of light spot is indispensable to improve the quality and performance of light spot. The spot quality analyzer developed by Jingyi Optoelectronics can be used to analyze the 2D/3D shape of the laser spot, the stability of the spot pointing, the size of the spot, the energy distribution, etc. To provide you with the most effective and valuable spot information and improve the laser spot production quality

-

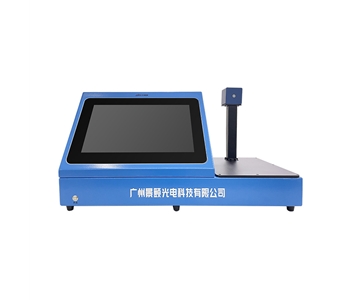

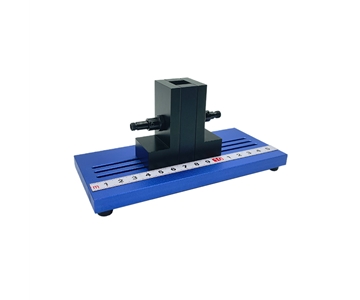

Quality Control of Photovoltaic Silicon Wafer for Contact Angle MeasurementSolar energy is one of the fastest growing renewable energy sources in the world. In order to ensure that the photoelectric effect can be used more effectively and economically, so as to further actively promote its development. Jingyi Optoelectronics uses the contact angle method to measure the wettability, which is non-contact and non-destructive, and the measured surface does not leave any traces. Therefore, it can be used to detect the cleanliness of photovoltaic silicon wafers and optimize wafer fabrication and quality assurance

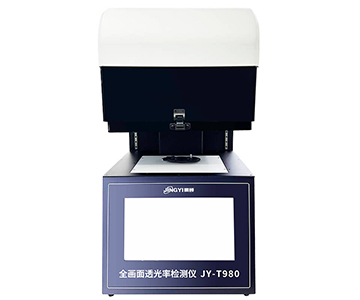

-

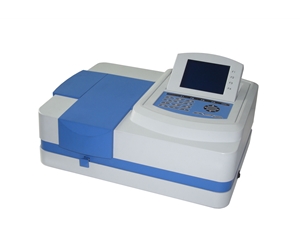

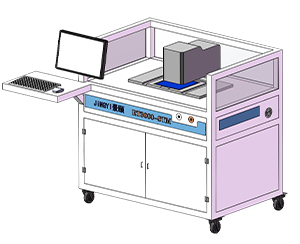

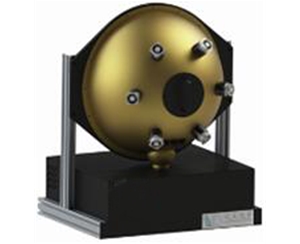

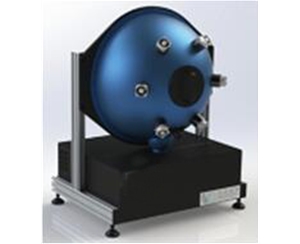

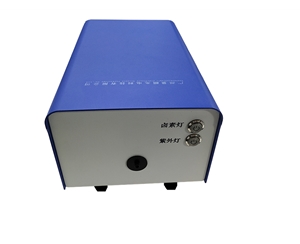

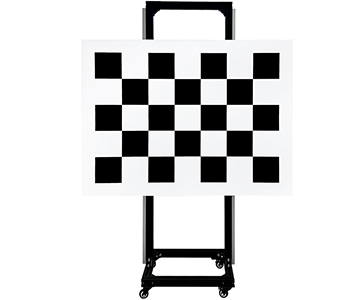

Photovoltaic glass transmittance detector schemeAs the global carbon neutralization process continues to accelerate, the cost of superimposed photovoltaic power generation continues to decline, and the economy continues to improve. The demand for high growth in the photovoltaic industry is more certain. Photovoltaic glass is an essential material for photovoltaic modules, which directly affects the power generation efficiency and service life of photovoltaic modules. After coating, photovoltaic glass can ensure a higher light transmittance, so that solar cells can generate more electricity. The transmittance of photovoltaic glass directly affects the power generation efficiency of photovoltaic modules. Photovoltaic glass transmittance detector developed by Jingyi Optoelectronics can be used for non-contact online rapid detection of photovoltaic glass to improve the transmittance of photovoltaic glass and effectively improve the power generation efficiency of photovoltaic modules